What are the functions of metal wire raceways? How do they differ from cable trays?

What are the functions of metal wire raceways? How do they differ from cable trays?

These are fundamental pieces of knowledge that everyone should understand. At the same time, it is also essential to clarify the differences between metal wire raceways and cable trays to develop a more comprehensive understanding of these two products.

Nowadays, many people use metal wire raceways during renovation, and their application is quite widespread. However, many may not be very familiar with their specific characteristics. The actual functions of metal wire raceways are something everyone should know. Additionally, it is important to understand the differences between metal wire raceways and cable trays to better grasp the features of these two products.

Main Functions of Metal Wire Raceways

Metal wire raceways must comply with various international certification standards, such as UL (U.S. electrical certification), CSA (Canadian standards certification), CE (conformity for European low-voltage equipment), DVE (German certification for electrical and electronic information technology inspection), and ROHS (international environmental protection certification).

Metal wire raceways are primarily used for laying wires, providing protection and ensuring neat and aesthetically pleasing wiring. They secure cables and help prevent fires or electric accidents caused by disordered wiring.

Metal wire raceways effectively prevent cables or rubber hoses from twisting and deforming between wire harnesses and trays. They feature a modern design, reasonable structure, high flexibility, and resistance to deformation. They are easy to install, reliable to use, and simple to disassemble and reassemble, with minimal sagging. They are commonly used in machinery such as machine tools for cables, oil pipes, air pipes, water pipes, and air ducts, serving both guiding and protective functions.

Metal wire raceways, also known as wiring ducts, distribution ducts, or trunking (varies by region), are electrical accessories used to neatly and securely arrange and fix cables such as power lines and data lines on walls or ceilings.

Differences Between Metal Wire Raceways and Cable Trays

Conceptual Difference: Cable trays are primarily used for laying power cables and control cables, while metal wire raceways are generally used for laying wires and communication cables.

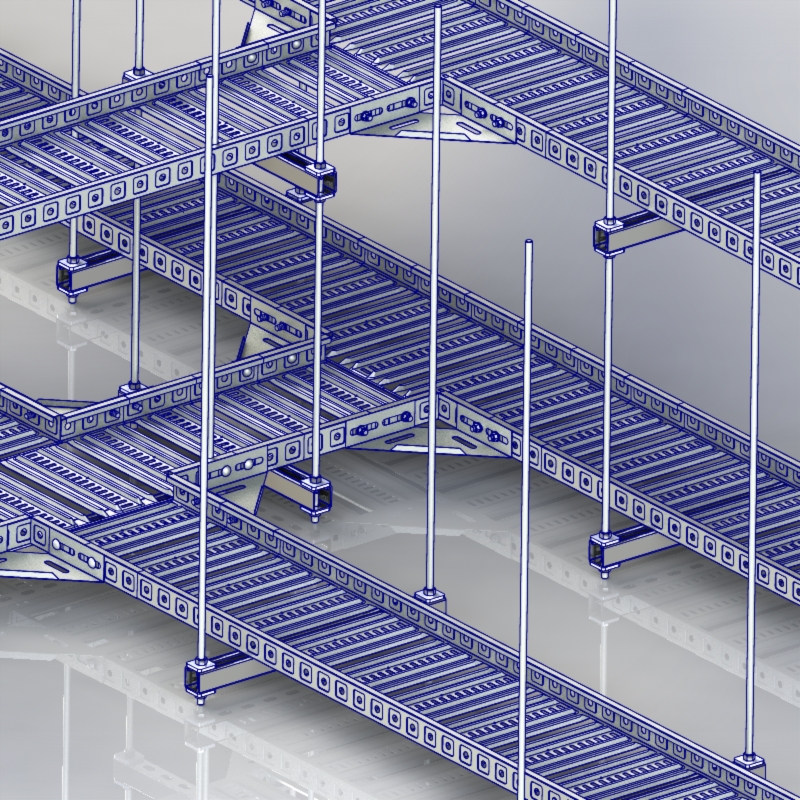

Size and Structural Differences: Cable trays are typically larger in size, especially in terms of bending radius and span, offering greater rigidity. They are often used in building floors, various distribution rooms, and other settings. Metal wire raceways are smaller, with bends mostly at right angles and relatively smaller spans.

Installation and Enclosure Methods: Metal wire raceways are mostly sealed structures with covers, commonly used for wire installation and frequently found in distribution cabinets and instrument cabinets. Cable trays, in some cases, are designed without covers and are mainly used for laying trunk cables.

Overall, metal wire raceways can be considered a subcategory of cable trays. Cable tray systems include brackets, accessories, supports, and hanging components, with main structures available in various forms such as solid, ventilated, ladder-type, or combination trays. The term “metal wire raceway” often refers to enclosed steel trough-type cable trays (which may be covered) suitable for laying wires and cables. Due to their enclosed metal shell providing certain shielding performance, they are often used for low-voltage circuits or control lines.