How to choose a cable tray and accessories?

◉ Toward the end of the project laying lines, wire and cable protection and erection methods of choice has become a lot of projects to end the problem, and the cable tray since the completion of this project is the only choice.

◉ However, there are many styles of cable tray, how to correctly and effectively select the cable tray and accessories is actually a learning experience. In most cases, the engineering side of the line provided by the construction plan, which indicates the layout of each part of the line. Which contains the contents of the line through the number of general, power size (or cable diameter), the number of shunts, access direction and so on. These data are generally non-professionals is difficult to understand, to be able to select the cable tray through the line construction drawings also need to analyze the data obtained in these contents of the calculation. The specific process is as follows:

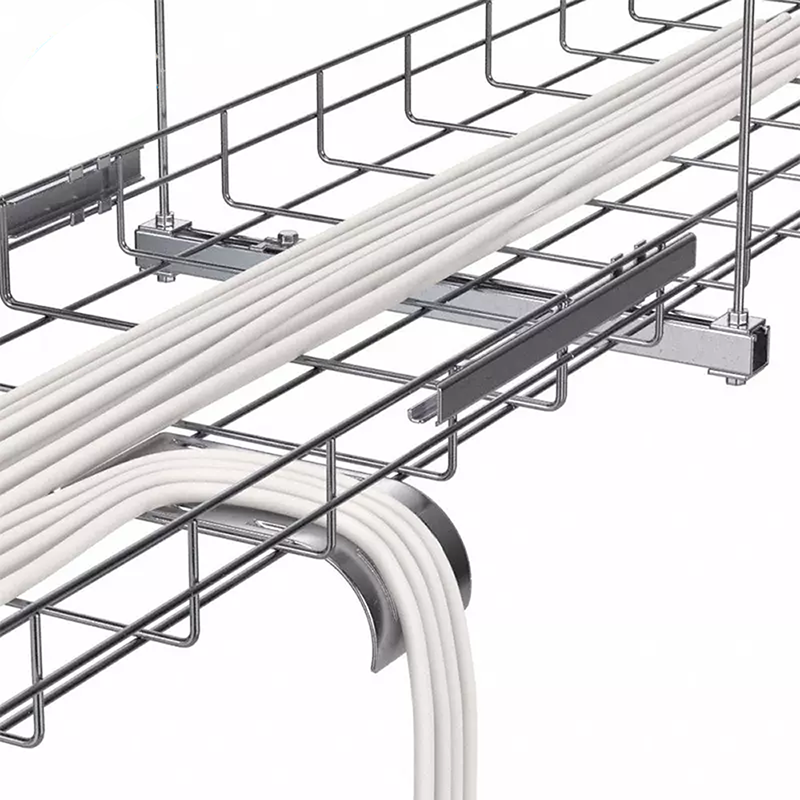

◉ 1, select the appropriate cable tray.

In accordance with the number of access to each part of the node and the power to calculate the diameter of each cable, arranged in accordance with 3 times the diameter of the cable spacing, resulting in the width of the cable tray. Then calculate the cross-sectional area of the cable tray according to 70 ~ 85% of the cooling space, divided by the cross-sectional area of the width of the cable tray to arrive at the height of the cable tray. If the cable tray layout location affected by the space can not be higher, or can not be wider. Porous cable tray can be used to increase the efficiency of heat dissipation, can be reduced to 35 ~ 50% of the space required for heat dissipation. In addition, it can also be used to solve the problem by not installing a cover plate.

◉ 2, calculate the line length.

First, in accordance with the drawings labeled circuit nodes to calculate the length of the pathway, all the length of the total length calculated in accordance with the method of one into the total length of the nodes connected to the parts of the relative distance. Then the drawings are labeled one by one. Thus, according to the length of each part of the length divided by the length of a single cable tray to get the number of roots, the number of tails into one. Thus confirming all positions required cable tray model specifications and quantity.

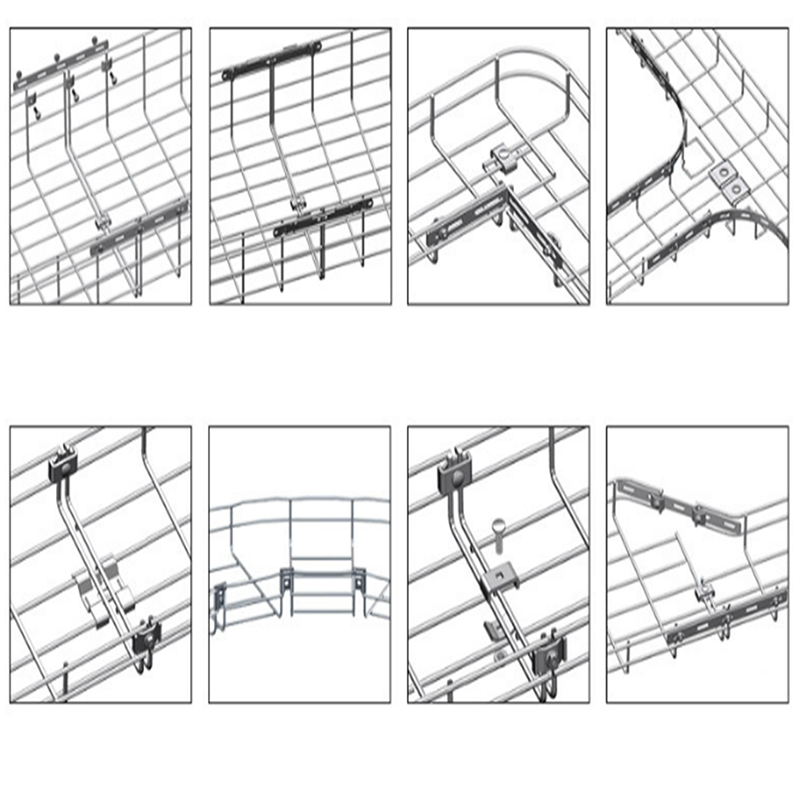

◉ 3, select the appropriate connector.

Each part of the cable tray size has been confirmed, the node position according to the vertical and horizontal vertical staggered position arrangement of the cable tray. There are intersecting or folding part of the joints need to be selected to carry out excessive, in addition to the size of the cable tray size of the joints also need to increase the reducer joints. Specific choices are as follows: First, the intersection of the position of the pathway for a number of ways to choose a number of joints, for example, a route is intersected in the middle of the end of the other way, which can be seen is a 3-way, so the choice of tee, the width of the cable trays of the three directions corresponds to the width of the tee joints. Then, for the horizontal direction of the corner, the horizontal elbow should be used, mostly 90 ° mainly, and vertical corners need to identify the alignment for the outside or inside the direction of the bend, select the cable tray outside the bend or inside the bend connector. Finally, at the end of the alignment can choose to close the cable tray plug.

◉ 4, choose to match the number of connectors and supports.

Cable tray mainly rely on the connection piece connection, general specifications of the type of cable tray at each end of two pieces of connecting pieces. After counting the total number of cable trays, multiply the total number by 2 to calculate the number of connectors required for the cable tray. Tee and 4-way fittings are calculated by multiplying the number of pathways by 2 to calculate the number of connecting pieces. Elbows and reducers are calculated by multiplying the total number of tabs by two.

The number of ground wires equals the number of connection tabs. The number of connection fasteners is calculated by multiplying the number of connection tabs by 6.

The number of cable tray bracket sets is calculated by multiplying the total number of cable trays plus the total number of elbows by 2. Special corners or mounting positions should be illustrated in additional drawings.

◉ The above four steps will be required for the project the number of cable tray and accessories counted out, then in the procurement of the order should be increased by about 5% of the spare parts. The number of single product is less than 20 pieces of at least one additional spare parts to ensure that the project is foolproof.

→ For all products,services and up to date information,please contact us.