Comparing the Advantages and Disadvantages of Aluminum and Stainless Steel Options

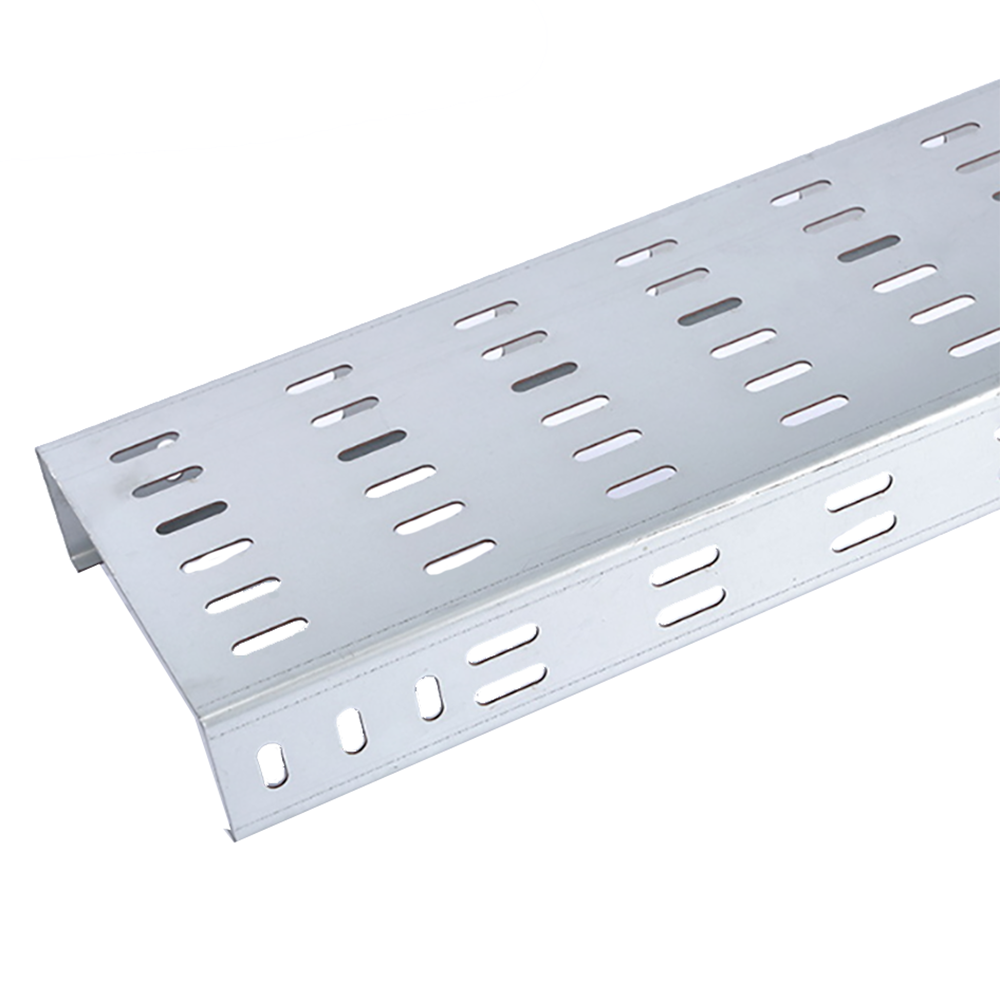

Cable tray plays a crucial role in the efficient and safe management of cables and wires in various industrial and commercial settings. It provides support, protection, and organization of cables, serving as a cost-effective alternative to more traditional methods such as conduit systems. The choice of material for cable trays is essential in determining their durability, corrosion resistance, and overall performance. This article aims to compare the advantages and disadvantages of two popular choices: aluminum cable tray and stainless steel cable tray.

Aluminum cable trays are widely known for their lightweight and durable nature. Their low weight makes them easy to install, reducing both labor and transportation costs. Being non-magnetic, aluminum trays are particularly useful in areas where electromagnetic interference may cause issues. They are also naturally resistant to corrosion, thanks to the formation of a protective oxide layer on their surface. This quality makes them suitable for outdoor applications, as they can withstand harsh weather conditions, including UV radiation. Additionally, aluminum cable trays often have a smooth and aesthetic finish, making them a visually appealing choice for many installations.

However, aluminum cable trays also come with a few disadvantages. While they are corrosion-resistant, they are not entirely immune to it. In highly corrosive environments, aluminum trays may require additional protective measures, like coatings, to prevent damage. Another consideration is the lower mechanical strength compared to other materials, which may limit their load-carrying capacity. Therefore, it is crucial to assess the weight and amount of cables to ensure the tray can adequately support them.

On the other hand, stainless steel cable trays offer excellent strength and durability. They have a high load-carrying capacity and can accommodate heavy-duty cables and wiring systems. Additionally, stainless steel trays have exceptional resistance to corrosion, making them suitable for the most demanding environments, including chemical plants and offshore installations. Their corrosion resistance is further enhanced by options for specialized coatings and finishes, such as hot-dipped galvanization. Stainless steel cable trays also maintain their integrity even at elevated temperatures, making them a reliable choice in fire-rated installations.

While stainless steel cable trays have numerous advantages, they are not without a few drawbacks. One primary concern is their higher cost compared to aluminum trays. Stainless steel is a premium material, which contributes to increased manufacturing expenses. The additional weight of stainless steel trays also makes transportation and installation more challenging and expensive. Moreover, stainless steel trays are susceptible to magnetism, which can hinder certain applications. In areas with intense electromagnetic fields, alternative materials or grounding techniques might be required to manage magnetic interference effectively.

In conclusion, both aluminum cable trays and stainless steel cable trays offer unique advantages and disadvantages. The ultimate choice depends on various factors such as the application, budget, and environmental conditions. Aluminum cable trays excel in their lightweight, corrosion resistance, and aesthetic appeal at a lower cost. On the other hand, stainless steel cable trays offer superior strength, durability, and resistance to extreme conditions, while being more expensive. Assessing these factors and consulting with professionals can help determine the most suitable option for each specific project.