- Home

- News

- What are the differences and advantages of stainless steel channel steel, aluminum channel steel, electro-galvanized channel steel, hot-dip galvanized channel steel

What are the differences and advantages of stainless steel channel steel, aluminum channel steel, electro-galvanized channel steel, hot-dip galvanized channel steel

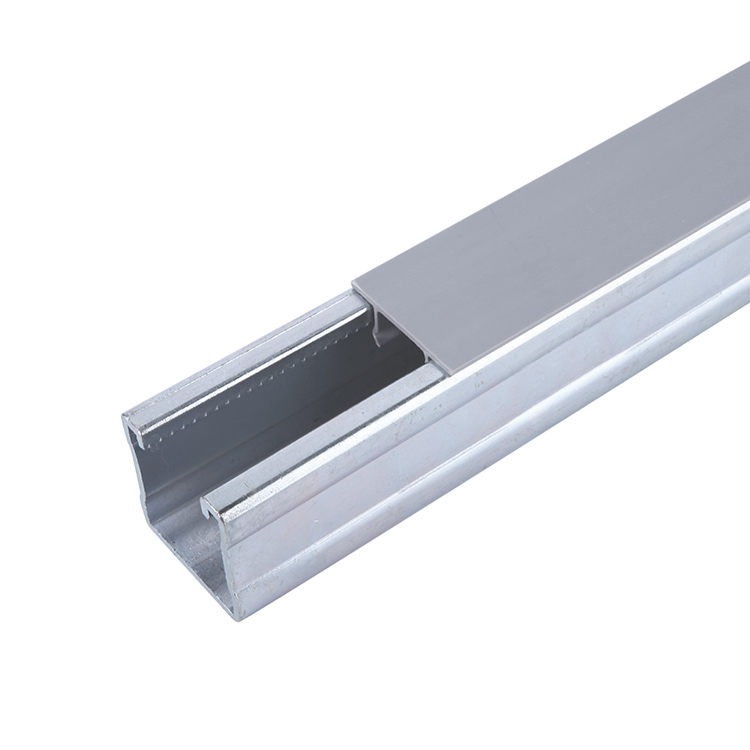

Steel Slotted Strut Aluminum C-Shape is a versatile and durable component that finds application in various industries. It is widely used in the construction, electrical and plumbing industries due to its sturdiness and ability to provide structural support. In this article, we will delve into the differences and advantages of stainless steel channels, aluminum channels, electro-galvanized channels, and hot-dip galvanized channels.

Stainless steel channels are highly corrosion resistant and suitable for outdoor and high humidity applications. It is made from a blend of steel, chrome and nickel for exceptional strength and longevity. Stainless steel channels are an excellent choice for environments where extreme temperature changes and severe weather conditions are prevalent. Its smooth, polished surface is aesthetically pleasing and requires minimal maintenance. Additionally, stainless steel channels are non-magnetic, making them ideal for electronic and medical equipment installations.

Aluminum channels, on the other hand, have an excellent weight-to-strength ratio. It is much lighter than stainless steel channel, easier to transport and install. Aluminum channel steel has high corrosion resistance, similar to stainless steel, but at a lower cost. It is often used in decorative applications due to its natural oxide layer which prevents further oxidation. Aluminum channels are also good conductors of electricity and are suitable for use in electrical installations.

Electro-galvanized channel steel is made by applying a layer of zinc through an electrolytic process. This produces a smooth, uniform, thin zinc coating with moderate corrosion resistance. Electro-galvanized channels are typically used in interior applications where corrosion is not a significant concern. It is cost-effective and has good formability, making it easy to bend and shape as desired. However, it may not hold up well in environments with high humidity or exposure to harsh chemicals.

Hot-dip galvanized channel steel goes through the process of immersing the steel in a bath of molten zinc. This creates a thick, durable and corrosion-resistant coating ideal for outdoor and high humidity environments. Hot-dip galvanized channel steel is known for its excellent rust resistance, making it ideal for marine and industrial applications. It also provides cathodic protection, which means that even if the coating is scratched or damaged, the adjacent zinc layer sacrifices itself to protect the steel below.

In conclusion, each channel steel has its unique characteristics and advantages. Stainless steel channels have excellent corrosion resistance and a polished appearance. Aluminum channel steel is light in weight and cost-effective. Electro-galvanized channels are suitable for indoor applications, while hot-dip galvanized channels provide excellent corrosion protection for outdoor and industrial environments. Environmental factors and desired properties must be carefully considered when selecting the appropriate channel for a particular application.