Introduction to key points of surface treatment of cable tray

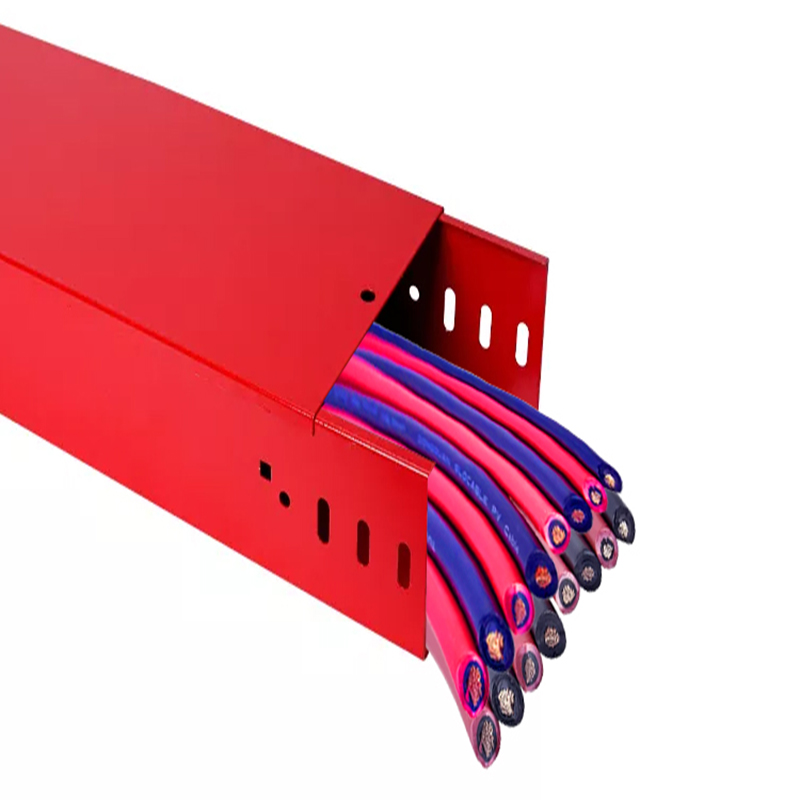

Bridging cable tray is suitable for cables. It has won wide application in industrial production, making the cable tray play a stronger role. Metal surface treatment here is necessary for people to detail the key points of the cable tray process on the surface. I hope it can help you.

1. There are many types of Qinkai cable tray, and different types of surface treatment process are different from the above regulations. Therefore, when developing the surface treatment process, we must pay attention to in-depth analysis of the actual problems and select the appropriate process.

2. When developing curved surface solutions, it is necessary to integrate their actual applications, and fully consider the provisions of flexible equipment to make the application more convenient.

3. During the surface treatment of cable tray, attention must be paid to the cable distribution equipment in the natural environment. At that time, the effectiveness of the cable is particularly important, and the strength and high-voltage cable can be set off. The surface treatment technology is the key in time division. If this is more advantages, better application effect can also be obtained

4. The demand for solutions on the surface of Qinkai cable tray has been fully considered in the whole process of actual construction transition and the level of its system. All projects are not only simple overall planning and construction of many different levels of professional knowledge support, but also the solution on the surface of goods must pay attention to this level. We have applied it to a huge progress.

It is forbidden to carry passengers during the whole installation process. If the site conditions determine that it is necessary, the equipment with safety precautions can carry passengers. For spot welding, the welding work must be done in the anti-corrosion solution. Generally, the customer applies anti-corrosion paint on the site.

When the cable tray is laid, the distance between the cable tray span node and the support plate point should be within 1/4 of the cable tray span. For large-span cable tray frame, it shall be connected with the bearing plate as much as possible. In the area with bends or tees, the points of the support plate shall be lifted separately

The cable in Qinkai cable tray is fixed by cable strap or metal cable snap ring. For horizontally paved cables, a support point is generally set up every 2m; The vertically paved cable shall be fixed once every 1-1.5m, and the beam end shall be fixed once when the design elevation changes.